Virtual models open up new possibilities in the development of electromagnetic actuators. Digital twins provide precise simulations even before the first prototype is built, accelerating the path to the optimal solution.

Digital Twin in Actuator Product Development – Efficient Simulation at Magnetbau Schramme

Alexander Grischin

Sales Manager

Quicklinks

- Virtual intelligence for real precision

- What is a Digital Twin in Solenoid Actuator Product Development?

- Use of Maxwell: The Simulation tool at Magnetbau Schramme

- Digital Twin Technology: Virtual Simulation does not replace, it complements Physical Testing

- Digital Twins in Practice: Load Analysis, Magnetic Field Optimization, Service Life

- Challenges of Digital Twins: Where the Limits of Simulation are

- Interview with Amit Simulation Expert at Magnetbau Schramme

- Efficiency gains through Simulation and Virtual Optimization

- Data-Based Development: The Path toward a learning Actuator

- How Magnetbau Schramme uses the digital twin strategically

- Outlook: Future trends in digital actuator development

- Conclusion: Virtual precision meets real experience

Virtual intelligence for real precision

In modern actuator development, speed, precision, and efficiency are decisive competitive factors. Today, customers expect not only the highest quality from linear solenoids, proportionalactuators, or magnetic valves, but also shorter development times and maximum power density.

To meet these demands, Magnetbau Schramme increasingly relies on digital twins. They make it possible to precisely simulate physical properties such as magnetic field distributions, thermal effects, or mechanical loads already in the early development stages. Virtual development complements the company’s decades of experience with a new digital toolbox that measurably accelerates innovation.

What is a Digital Twin in Solenoid Actuator Product Development?

A digital twin is a virtual model of a real product or system. In actuator development, it combines all relevant data and parameters of a magnet into a digital simulation model, from the coil to the armature stroke to the electromagnetic forces.

In contrast to conventional CAD models, which only represent geometry, the digital twin allows the simulation of real operating conditions:

- How does the magnetic field within a proportional solenoid change when the air gap changes by a few micrometers?

- What temperature does the magnet coil reach when the actuator is operated continuously with a specific current?

- How do magnetic saturation or eddy current losses affect the dynamics of a switching solenoid?

Through the combination of various physical disciplines — from electromagnetics to thermodynamics to mechanics — a comprehensive virtual test environment emerges. This significantly shortens the physical prototype phase.

Use of Maxwell: The Simulation tool at Magnetbau Schramme

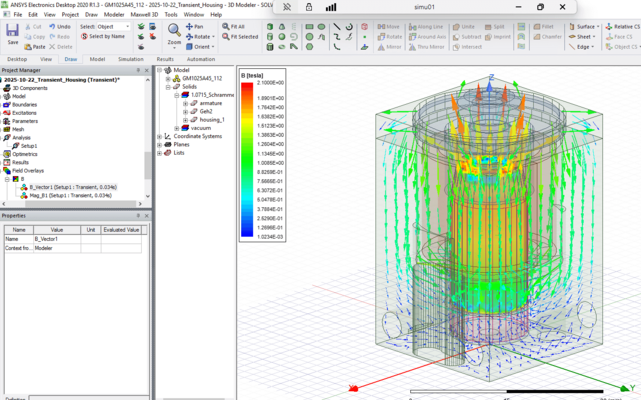

For electromagnetic simulation, Magnetbau Schramme uses Ansys Maxwell, one of the leading finite element platforms (FEM) for 2D and 3D analyses of electromagnets such as holding magnets, valve magnets, or electromagnetic clutches and brakes.

With Maxwell, highly precise field analyses can be carried out, including:

- Magnetic flux densities and forces in the air gap

- Inductances and magnetic saturations

- Losses in ferromagnetic materials-

- Transient effects during switching processes or current pulses

This allows Schramme’s engineers to decide already in the digital model whether a certain geometry or material selection meets the requirements for dynamics, force characteristics, and energy efficiency.

The result: fewer physical prototypes, faster iterations, and higher development precision.

Digital Twin Technology: Virtual Simulation does not replace, it complements Physical Testing

Despite advanced simulation technologies, the digital twin does not replace real-world testing. Especially for electromagnetic actuators used in safety-critical applications such as braking systems, valve control, or hose clamp valves, validation on test benches remains essential.

However, simulation ensures that real tests become more targeted and far more efficient. Only the most promising design variants move into the prototype phase. At the same time, simulation and test data can learn from each other: findings from tests flow back into the simulation model, making the digital twin continuously more precise.

Digital Twins in Practice: Load Analysis, Magnetic Field Optimization, Service Life

The fields of application for digital twins in the development of electromagnetic actuators are diverse:

1. Magnetic Simulations

- Optimization of flux density distribution for solenoids, holding magnets, or magnetic bearings.

- Reduction of stray fields and minimization of magnetic saturation.

- Analysis of transient magnetic fields in proportional solenoid actuators with variable current control.

2. Thermal Analyses

- Determination of heat generation in magnet coils under continuous operation.

- Influence of heating on resistance and magnetic force.

- Simulation of cooling and heating cycles in double-stroke or valve actuators.

3. Mechanical Load Models

- Simulation of friction, wear, and elasticity in moving actuator components.

- Investigation of deformation and material stresses under extreme load cycles.

4. System Integration

- Coupling the solenoid model with hydraulic or pneumatic components (e.g., in seat valves or slide valves).

- Analysis of interaction between electromagnetic linear drive and control electronics (e.g., for precise regulation of proportional actuators).

- These multiphysics models make the digital twin a central tool in product development.

Challenges of Digital Twins: Where the Limits of Simulation are

Although digital twins are highly powerful today, their implementation comes with technical and organizational challenges. Especially in electromagnetic actuator development, it becomes clear that precision in the virtual space is only achieved when models, material data, and real measurements are tightly integrated.

1. Material Data and Manufacturing Tolerances

The accuracy of a digital twin strongly depends on the material characteristics used.

Even small deviations in permeability, manufacturing-induced changes in B-H curves, or variations in air-gap tolerances can influence real behavior.

For Magnetbau Schramme, this means: material libraries must be continuously maintained and compared with test data from production to keep simulations reliable.

2. Complexity of Multiphysics Models

An actuator combines electromagnetic, thermal, and mechanical processes in a very compact installation space.

Accurately coupling these disciplines requires detailed models and significant computing power.

The depiction of dynamic events, such as current rise, eddy current losses, or temperature gradients, is especially challenging.

3. Validation and Model Maintenance

A digital twin is not static but a learning model.

To ensure reliability, it must be regularly validated with new measurement data:

- Force curves

- Switching times

- Temperature profiles

- Current consumption

This continuous comparison requires a structured process.

4. Edge Cases and Nonlinear Effects

In extreme operating ranges — high currents, fast switching cycles, critical temperatures — nonlinear effects appear, such as:

- magnetic saturation

- hysteresis

- changing friction conditions

- temperature-dependent resistances

Here, physical test benches remain indispensable.

5. Integration Into Development Processes

Digital twins change how development and test teams work.

Data structures, simulation processes, and interfaces to manufacturing must be harmonized — a demanding task that pays off over time.

Building this infrastructure is challenging, but it pays off in the long term because expertise is centralized and development cycles are shortened.

Interview with Amit Simulation Expert at Magnetbau Schramme

In our conversation with Amit, we asked him various questions about the creation of digital twins, modeling in ANSYS Maxwell, and the merging of simulation and real measurement data:

How is a digital twin built at Schramme (data, models, tools)?

“At Schramme, the digital twin of an electromagnetic actuator is created based on an electromagnetic model in Ansys Maxwell. The fundamental magnetic material properties, such as B-H curves and permeability, come from our extensive internal material library or are determined in the laboratory for special materials (e.g., hydrogen applications).

Electrical input parameters and mechanical loads are derived from customer-specific application requirements. By combining this material data, electrical specifications, and mechanical boundary conditions, a highly precise digital twin is created that realistically represents the electromagnetic and mechanical behavior of the actuator.”

Which parameters are modeled in Maxwell (magnetic, thermal, mechanical)?

“For the coil development, both magnetic and mechanical properties are simulated in Ansys Maxwell, including magnetic flux distributions, force-stroke curves, inductance curves, and mechanical interactions caused by magnetic forces.

Thermal analysis is performed using an internally developed thermal model based on extensive tests of various electromagnet series. With this, we can reliably predict heating behavior and saturation temperature during continuous operation.”

How are simulation and real measurement data merged?

“Simulations are carried out even before the first prototypes are manufactured. Once the first electromagnets are produced, we compare their real measured data, such as force behavior, current consumption, or switching times, with the results of the digital twin. Based on this comparison, the simulation model is validated, which further increases prediction accuracy for the specific customer application.”

What successes or surprises have occurred in projects with digital twins?

“Across numerous electromagnet types, our digital twins match practical measurement results very well. This allows us to make reliable predictions early in the development process and optimally tailor the solution to the customer’s application. Occasionally deviations occur, usually in complex or heavily stressed components where manufacturing processes may slightly alter magnetic properties. Such effects are identified in tests, and appropriate manufacturing steps are implemented to match real behavior closely with the simulation.”

We thank Amit for the fascinating insights, which show how closely simulation and real measurement data are linked at Schramme and the high maturity level our digital twins have now reached.

Efficiency gains through Simulation and Virtual Optimization

The introduction of digital twins transforms the entire development process. Where trial-and-error once dominated, data-driven iterative cycles between model and reality now emerge.

The key advantages at a glance:

Reduced development time

Simulation replaces numerous physical prototypes, a decisive time gain, especially for customer-specific actuation systems.Cost savings

Fewer prototypes, fewer test setups, and early error detection save significant resources.Increased product quality

More precise modeling of magnetic and thermal processes allows performance parameters to be adjusted in a targeted manner.More design freedom

Engineers can virtually test unconventional geometries before they incur real manufacturing costs.- Sustainability

Reduced material consumption and fewer test cycles lower the ecological footprint of product development.

Data-Based Development: The Path toward a learning Actuator

A decisive step toward the future is the integration of the digital twin with real operating data. Once an electromagnetic actuator is in operation, sensor data; temperature, current consumption, switching cycles, can be fed back into the virtual model.

This creates a “living” digital twin that mirrors the real product’s state in use. Based on this data, it is possible to:

- create service life predictions for solenoid valves or clutches,

- plan maintenance intervals proactively,

- and detect faults early, before they occur in the field.

This connection between simulation and IoT data leads to data-driven product development, in which the digital twin becomes not only a development tool but also a service tool.

How Magnetbau Schramme uses the digital twin strategically

At Magnetbau Schramme, the use of Maxwell simulations has long been more than just a technical tool, it is strategically integrated into the development process.

Already in the concept phase, a digital twin is created for every new actuator solution. It accompanies the product through all phases:

- Concept & design: FEM analyses, geometry optimization, material selection

- Prototyping: validation of simulation results, adjustment of the models

- Series development: use of the models for variant creation and customer-specific adaptations

Especially with complex products such as reverse-stroke solenoids or valve actuators, it becomes evident: the combination of modeling and simulation significantly shortens development cycles and increases the robustness of the results.

Outlook: Future trends in digital actuator development

The journey of digital twins is only just beginning. Future developments will be characterized by:

- AI-supported model optimization: algorithms that automatically adapt geometries or coil windings to target parameters.

- Automated co-simulation framework: combining Maxwell with fluid and structural mechanics tools.

- Real-time twins in manufacturing: inline simulations that evaluate quality data directly during production.

- Standardization and reuse: building an internal “library” of digital twins for common magnet types (e.g., standard solenoids or proportional magnets).

This will make the digital twin a permanent part of the product DNA, an instrument that preserves know-how and is continuously developed across generations of engineers.

Conclusion: Virtual precision meets real experience

Digital twins are revolutionizing the development of electromagnetic actuators, merging theory, simulation, and practice into an intelligent development process. For Magnetbau Schramme, this means:

- higher development speed,

- deeper insights into physical relationships,

- and the ability to create customized solutions for the most demanding applications.

With tools such as Ansys Maxwell and the expertise of Schramme’s engineers, a synergy emerges between simulation and craftsmanship, between digital precision and decades of experience in magnetic technology.

Digital twins are shaping the future of actuator development, and at Magnetbau Schramme, virtual intelligence and real engineering expertise merge into technological excellence.