Rapid development, validation & industrialisation.

Magnetbau Schramme

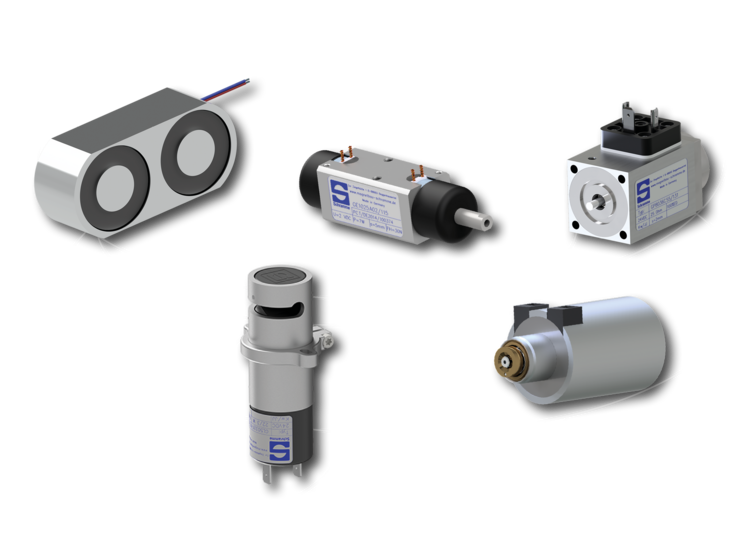

Innovative electromagnet technology - powerful, customised and always with highest quality.

Innovative electromagnet technology - powerful, customised and always with highest quality.

Our solutions are as diverse as your project and your requirements. Our engineers design the missing component for your success - customised and produced promptly.

With over 50 years of experience, we develop and manufacture electromagnetic products for various applications. Thanks to our quality focus, ISO 9001 & IATF 16949 certification, flexibility in terms of quantities and high vertical integration, we offer fast implementation and cost-sensitive solutions with the highest quality. Our team of experts will accompany you personally from the initial enquiry through to series production.

Marco Kiene

Management | CSO

Expertise combined with innovation & enthusiasm

With more than 50 years of experience, we are your reliable partner for the development and manufacture of electromagnets for a wide range of applications.

With our quality promise, ISO 9001 and IATF 16949 certifications, as well as our high flexibility in terms of quantities and in-house production depth, we guarantee you fast and cost-efficient solutions with the highest quality at all times. Our experienced team is at your side from the initial enquiry through to series production.

You can expect exciting challenges and innovations with plenty of room for personal development in a pleasant working environment. Collaboration is very important in our team - you will not only find colleagues here, but also friends.

What makes Magnetbau Schramme GmbH & Co. KG special?

Magnetbau Schramme GmbH & Co KG is a leading provider of innovative electromagnetic solutions with over 50 years of experience. The company offers customised products that are used in various industries and guarantees the highest quality thanks to IATF 16949 certification and a high specific vertical integration.

What certificates does Magnetbau Schramme hold?

Magnetbau Schramme is certified to ISO 9001 and IATF 16949, guaranteeing the highest quality and safety standards. These certifications demonstrate the company's commitment to quality, continuous improvement and reliable products that meet the highest requirements in various industries.

How quickly can Magnetbau Schramme deliver products?

Magnetbau Schramme is known for fast production times and flexible manufacturing that is customised to meet customer requirements. Thanks to efficient processes and a high degree of in-house production depth, products can be developed and delivered at short notice in order to meet customer requirements and realise projects promptly.

What services does Magnetbau Schramme offer in addition to product manufacturing?

In addition to manufacturing, Magnetbau Schramme offers comprehensive consulting and development services. Its team of experts supports customers in concept development, prototype production and validation of new products. This comprehensive support ensures customised solutions and smooth integration of the products into existing systems and processes.

Where are the locations of Magnetbau Schramme GmbH & Co. KG?

The head office of Magnetbau Schramme GmbH & Co KG is located in Germany. The company also has a subsidiary in Yangzhou, China, to serve customers worldwide. With modern production facilities and a network of partners, Magnetbau Schramme ensures global presence and local support.