Magnetbau Schramme

Magnetbau Schramme GmbH & Co. KG has been successful in the development and production of electromagnetic products for over 50 years and is firmly established on the market. Find out more about us here.

Schramme moves, stops, switches and controls

Creating sustainable solutions with expertise

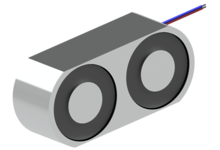

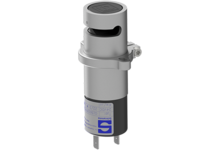

Magnetbau Schramme GmbH & Co. KG is operating globally, family owned and has its headquarter in Deggenhausertal, Baden-Württemberg. Since 1975, we have been developing and producing a wide range of electromagnetic actuators, including linear solenoids, holding solenoids, solenoid valves and complex electromagnetic components.

The majority of our series products are the result of customised product developments and are used in a wide range of industries and applications. These high-quality products are often indispensable components in our customers' systems.

Magnetbau Schramme sets value on efficient processes and uses the LEAN management philosophy in all areas of the company. The company is certified acc. ISO 9001 and IATF 16949 and our team consists of about 150 people in Germany.

Facts, figures and data

Information from Schramme at a glance

From trucks to church organs, from escalators to coffee machines, from lung ventilators to production plants - our products make a valuable contribution (almost) everywhere.

Do you need more information about Schramme or would you like to make an enquiry? Then please do not hesitate to contact us.

Company history

Electromagnets since 1975

Magnetbau Schramme has been developing and producing high-quality electromagnetic actuators as a family owned company since 1975.

Founded as a department of a Markdorf-based company specialising in the development and production of simple shackle magnets, for example for cash register systems.

The company appears on the market for the first time under the name "Magnetbau Schramme GmbH".

Due to growth and the need for modern production facilities, the company relocates its headquarters to Deggenhausertal.

Investment in a clean room due to new customer requirement (IATF 16949).

Additional production hall for the localisation of CNC production and the plastic injection moulding area.

Dr Joachim Hümmler takes over as Managing Director and is responsible for the strategic development of the company.

Our values & philosophy

WE! create a special attraction

As a specialist in customised electromagnetic solutions, we move, hold, switch and control the world - from excavators to church organs, from escalators to coffee machines. With our values and innovative products, we shape the future and make life a little better (almost) everywhere.

Our values at Magnetbau Schramme

At Magnetbau Schramme, values such as respect, responsibility, reliability and team spirit take centre stage. Integrity, honesty and humanity characterise our actions, while determination and a willingness to innovate drive us forward. With fairness, professionalism and passion, we create an environment of trust - for our employees, customers and partners. Together we shape the future.

What makes Schramme special

Your partner for customised solutions

Magnetbau Schramme offers customised solutions and the best customer service. We support you from the initial enquiry through to the fully developed electromagnet ready for series production - all from a single source. Our ISO 9001 and IATF 16949 certifications guarantee the highest quality standards, while over 50 years of experience make us experts.

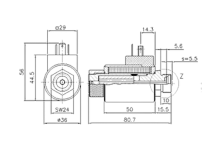

Thanks to our high vertical integration with machining, plastic injection moulding and various assembly environments, as well as our own prototyping and testing facilities, we are flexible and can respond quickly to your requirements. Whether small quantities or large series - we offer variable production options. Industry diversity, personalised support and manageable cost structures make us the preferred partner for innovative electromagnetic solutions.

Sustainability

Climate-neutral company since 2018

We understand the term sustainability to mean the conscious behaviour of ecological, economic and social factors. These form the three pillars of sustainability, according to which we orientate ourselves together with our customers, cooperation partners, suppliers, employees and many others.

We are climate-neutral and certified

We operate sustainably and have been climate-neutral since 2018. We are one of the first companies in our industry to be certified climate-neutral. By purchasing climate certificates to offset greenhouse gas emissions, we support developing countries in implementing sustainable measures.

- Brazil - Forest conservation project for endangered species

- Mongolia - cooking cookers

- Mexico - wind energy